Leftovers

Home -

Recipes - Butcher

Charts -The Wood - Que

Tips - BBQ Lingo

Smokers -

Que Gear - Pitmasters - BBQ Nation

-

Leftovers -

About Us

Leftovers

is a place for everything that's, well, leftover.

Kind of a potpourri of important odds and ends that don't

fit anywhere else.

How To Build A Quick And Simple Concrete

Block BBQ Pit

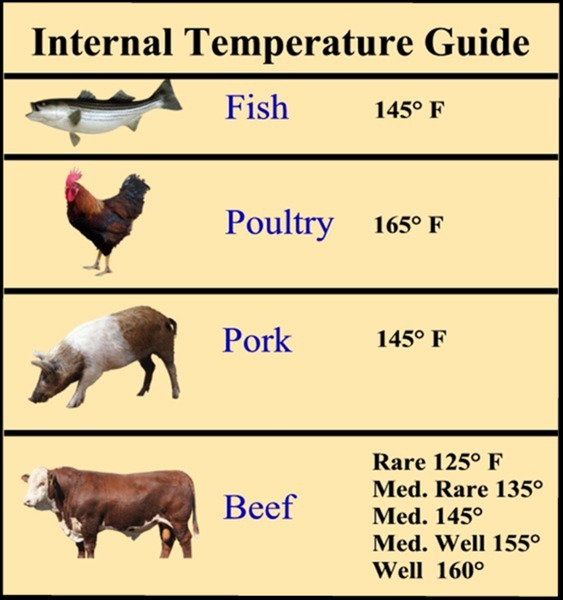

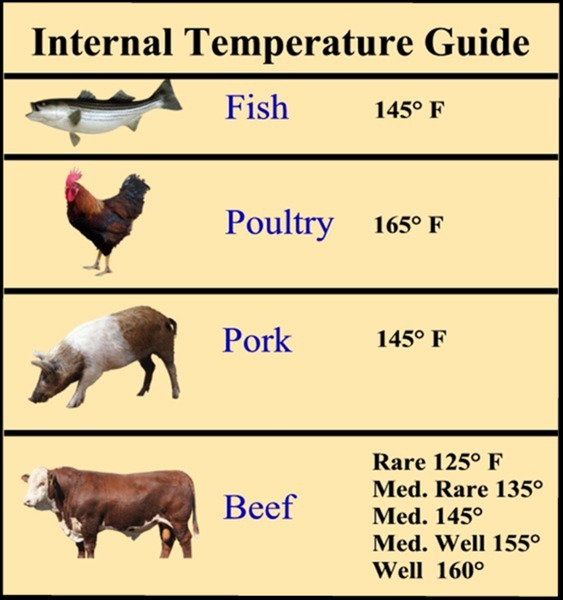

New Guidelines For Meat Done

Temperatures

On

May 24th., 2011, the USDA lowered the recommended safe cooking

temperature for whole cuts of pork from 160 ºF to 145 ºF with

the addition of a three-minute rest time. The new cooking

guidelines comes after a Pork Check Off research project

performed by an independent research firm, shows that pork can

be consumed safely when cooked to an internal temperature of

145 degrees Fahrenheit, followed by a three-minute rest time.

The new recommended temperature is a significant 15 degrees

less than what was previously recommended and typically will

yield a finished product that is pinker in color than most

home cooks are accustomed to and may be a little hard to take

at first, or second. This new temperature does, however, help

a great deal with keeping pork moist, which can be difficult

with many cuts of pork. The revised recommendation applies to

pork whole-muscle cuts, such as loin, chops and roasts.

Ground pork, like all

ground meat, should be cooked to 160 degrees Fahrenheit.

For beef, veal, and

lamb cuts, the safe temperature remains unchanged at 145 ºF,

(Not sure, but I think it's illegal to cook a steak to 145

degrees in Texas) and the department has added a three-minute

rest time as part of its cooking recommendations with those as

well.

Poultry: The safe

cooking temperature for all poultry products, including ground

chicken and turkey, stays the same at 165 ºF.

Of course you should always follow all safety recommendations

regardless of topic, but remember, these are the "Safe Done

Temperature" recommendations, not necessarily the "Good Done

Temperature" recommendations. When I served my wife her first

pork chop cooked to these new temperatures, she promptly ask

me to return it to the grill. She loves her steak rare, but a

pink pork chop did not fit her perception of appetizing, or

done.

Recommended Done Temperatures for

Meat

(Notice

the temperatures for beef shows various doneness, the

recommended "safe" temperature is still 145 F.)

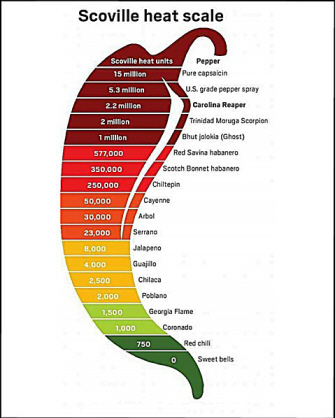

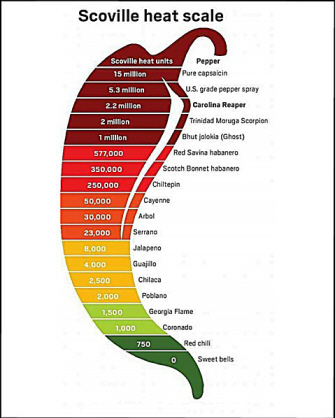

Here's a quick chart you can use when

trying to choose the right chili pepper for your recipes.

Lump

Charcoal vs Briquettes

It all

begins with a guy named Henry Ford. That's right, the car guy.

Ford was a genius in more ways than just the assembly line.

When he started producing cars, he soon found he had a huge

stockpile of scrap lumber left over from the manufacturing of

his Model T’s, which were in fact made largely of wood. Ford,

known as the "King of Penny Pinchers", could not bear the

thought of just throwing all these precious scraps away, so in

the 1920s, Ford started a manufacturing process using the wood

scraps, to make charcoal briquettes (spelled briquet on the

Kingsford bags).

The first patent for Briquettes, however, was actually filed

by Ellsworth Zwoyer, in 1897, who invented the process in

order to use the briquettes to fuel his power plants. The

exact details are unknown as to what agreement was actually

made between the two, but a few years after receiving his

patent, Zwoyer allowed Ford to manufacture and market the

charcoal briquettes. Ford started marketing his briquettes for

home use under the name Ford Charcoal.

E.G. Kingsford, Ford’s cousins husband, had helped broker the

location for the first factory. The company was later renamed

in his honor,

"Kingsford Charcoal".

Due to Ford’s mass production process and clever marketing of

the charcoal briquette, barbecuing with charcoal soon became

the most popular way to fire the home grill as well as many

other uses in the personal and business sectors.

So which is better, lump or

briquette? Either one will cook your food about as well as

the other. The main difference is found in the processing.

Lump coal is just that, the

charcoal left from burning wood, chopped up into chunks or

lumps.

With lump coal you are pretty sure

of getting the same type of wood throughout and without any

additives that may cause unpleasant taste in your food.

Pure, plain and simple, however the different size chunks

can make using it a bit more awkward.

Briquettes are also made from the

charcoal left from burning wood, however, it is then ground

to a granular powder, a binder is added and they are

compressed into uniform cubes. This method often uses a

mixture of various left over wood scraps, so they may

contain one or many different types of wood as well as

adhesive binders. Once ground and compressed it all looks

the same, but just like smoking with different woods,

briquettes made with various mixtures of wood, can have

their own flavor and aroma. The flavor you get from

briquettes depends largely on the wood scraps and type of

chemical binders used in the processing. Even briquettes

from the same bag could have different compositions. It is

possible the steak you grill next week might taste a slight

bit different than the one you grilled today if your using

charcoal briquettes. Though a little less pure, briquettes

do offer a more uniform shape and ease of use than their

lump cousin, especially in automated delivery systems.

Bottom line, if your a purest at

heart, stick to the lump, but I've never heard anyone

complain about the flavor from their briquettes.

Note:

Some manufacturers are now

making custom briquettes made from only one type of wood,

such as oak, pecan or hickory. Kingsford began making this

custom charcoal for Competition BBQ Teams who needed to use

briquettes in their smokers chute deliver system, but wanted

a specific wood for flavor.

They now have a complete line of

this custom charcoal available to the public marketed under

their "Competition Charcoal" label.

![]()