Guitar Straps -

Banjo Straps - Mandolin Straps - Leather

Guitar Straps

- Custom Guitar Straps

Creating Your Design

[HOME]

[DESIGN] [PRICING/ORDERING]

[SEND PAYMENT]

[PHOTO GALLERY 1] [PHOTO GALLERY 2]

[PHOTO GALLERY 3]

[PHOTO GALLERY 4]

[PHOTO GALLERY 5]

[PHOTO

GALLERY 6]

[SCRAPBOOK] [ABOUT US]

[CONTACT US] [SITE MAP]

[LINKS]

The design and craftsmanship that goes into

the making of a fine strap is aimed toward complimenting the look of your valued

instrument as well as the style and individuality of the musician. All of our straps

are designed and handmade one

at a time, to insure they reflect the true expression of each individual

artist.

Equally important in the construction of a

strap, are comfort and durability. Anyone who has had a guitar hanging on

their shoulders for hours on end certainly knows the need for comfort, at the

same time the conditions and surroundings musicians and their instruments are

often subjected to can be extremely harsh. Therefore beauty, comfort and

durability must be equally incorporated into the design and construction of the

strap in

order for the finished product to fully meet the needs of the musician.

Since all of our

straps are custom made to

suit the needs of each individual customer it is impossible to describe just one

type of material or construction method used. Obviously straps with inlay,

without inlay, different choices of padding, various designs, etc., will differ from

each other. However there are some basic features that should be mentioned.

We use only first grade, veg-tanned

hides. These hides are tanned using natural products in the tanning

process, such as tree bark and other vegetable products. This insures the

fibers in the leather are not weakened or damaged which can often occur with

aluminum or chromium salt processing. This chemical salt process is most

often used in the making of garment leather where a softer and more supple

texture is needed. This is fine for clothing but you wouldn't want to make

a pair of boots out of a leather vest. In addition, only veg-tanned

leather can be used to properly carve and hand tool.

Our

straps (unless otherwise specified)

are made using single layer, top grade double-shoulders. This is one of

the thickest and most durable parts of the hide, providing maximum fiber

strength with minimal stretch. By using this thick, high grade leather,

the need for stitching, which can soon become frayed and break, is

eliminated. Similar to a pair of new leather boots, your strap will be

slightly stiff at first, but with use will soon become more pliable and actually

conform to the musicians individual style and stature. Once broken in, it

should provide years of beauty, comfort and dependable service with minimal care.

An added benefit to using all natural tanned

leather, is the occasional distinctive markings. Small imperfections in

the hide caused by range marks, barbwire scratches, etc., give each strap it's

own unique character.

As always, if you have any questions please

feel free to contact us.

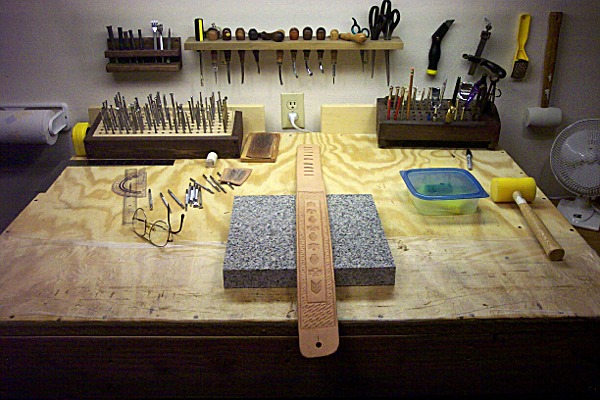

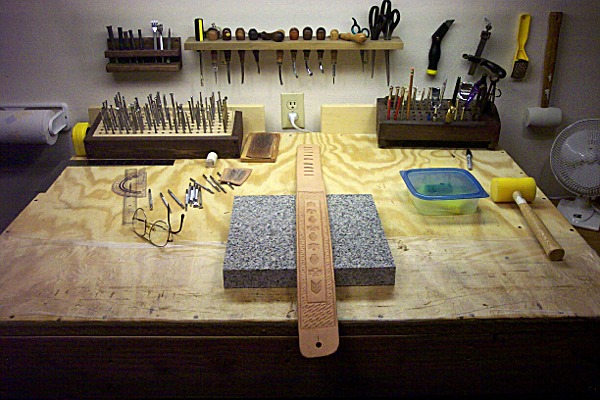

MAKING

A STRAP

|

|

|

|

|

It all starts swith a big piece of cow hide! We use only the highest

quality Veg-Tanned double shoulders. | A

strip is then cut to the specified width of the strap. |

The

desired pattern is traced and cut. Adjustment slots and

attachment holes are punched. |

The

edges are finished by beveling, applying a treatment and then burnishing. |

|

|

|

|

| The

strap is then dampened with a casing solution, placed in an air tight bag

and allowed to cure. |

Once

cased, the strap is ready to begin laying out the desired design for

carving and tooling. |

Carving

and tooling is continued until all designs, lettering and borders are

completed. |

The

"tail" or adjustment strap is traced, cut and edged in the

same manner as the strap. |

|

|

|

|

| Once

the strap has been allowed to dry, the dyeing and painting process

begins. |

After

the dye and paint have been allowed to dry, the padding is cut, fitted

and glued to the back. |

Finally

the protective finish is applied and allowed to dry. |

There

it is! The strap is now ready to be packaged and shipped to our

customer. |

|

Once the

order has been received, the lay out for the desired pattern,

designs and strap type are created. These are then sent to

our shop to begin handcrafting of the product. Once the item is

completed, it is inspected, packaged and shipped. Depending on

the complexity of the strap, designs, staining and painting, the

production process usually takes from 2 to 8 weeks to

complete. All in all it can be a rather lengthy process,

but that is the only way to manufacture a truly custom strap. We hope you enjoyed this short presentation and

maybe have a better understanding of the time and care we put

into our products. If you have any questions or need

further information, please feel free to contact us. We

want you to be as confident and comfortable as possible about

placing your order with us.

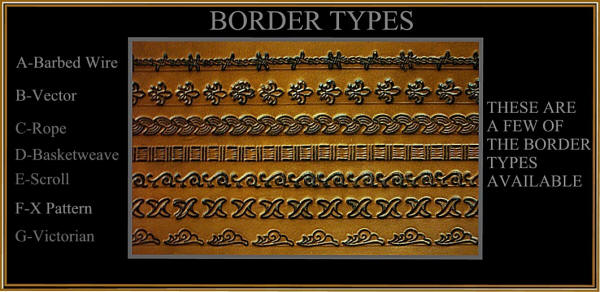

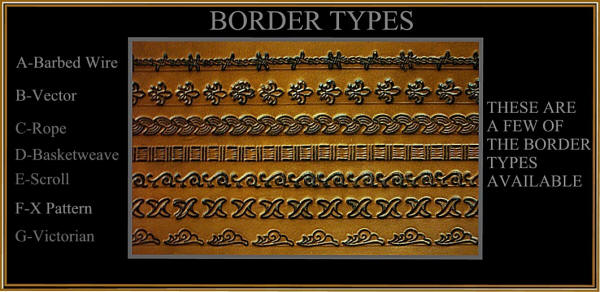

Borders

and Edges

Below are

few examples of the various border designs available. These borders

can greatly add to the finished look of a fine leather strap.

Thank you for your interest in

"Ovation

Leather Design"

Contact

Information

Ovation

Leather Design

Phone:

915-215-2317

El Paso, Texas

Guitar Straps -

Banjo Straps - Mandolin Straps - Leather

Guitar Straps

- Custom Guitar Straps

"The Signature Of

Success"

|